Reliable Solutions for Recycling Transformer Oil Without Compromise

Wiki Article

Transform Waste Into Value With Advanced Transformer Oil Recycling

The makeover of waste right into value presents a critical possibility within the electric sector, especially via the lens of sophisticated transformer oil recycling. By utilizing state-of-the-art technologies, such as vacuum distillation and filtration systems, organizations can recoup crucial resources from utilized transformer oil while alleviating environmental risks. This method not just improves operational performance however likewise lines up with expanding sustainability needs. As markets significantly prioritize eco-friendly initiatives, the effects of these advanced recycling approaches require closer exam to understand their full capacity and effect on the market.Comprehending Transformer Oil

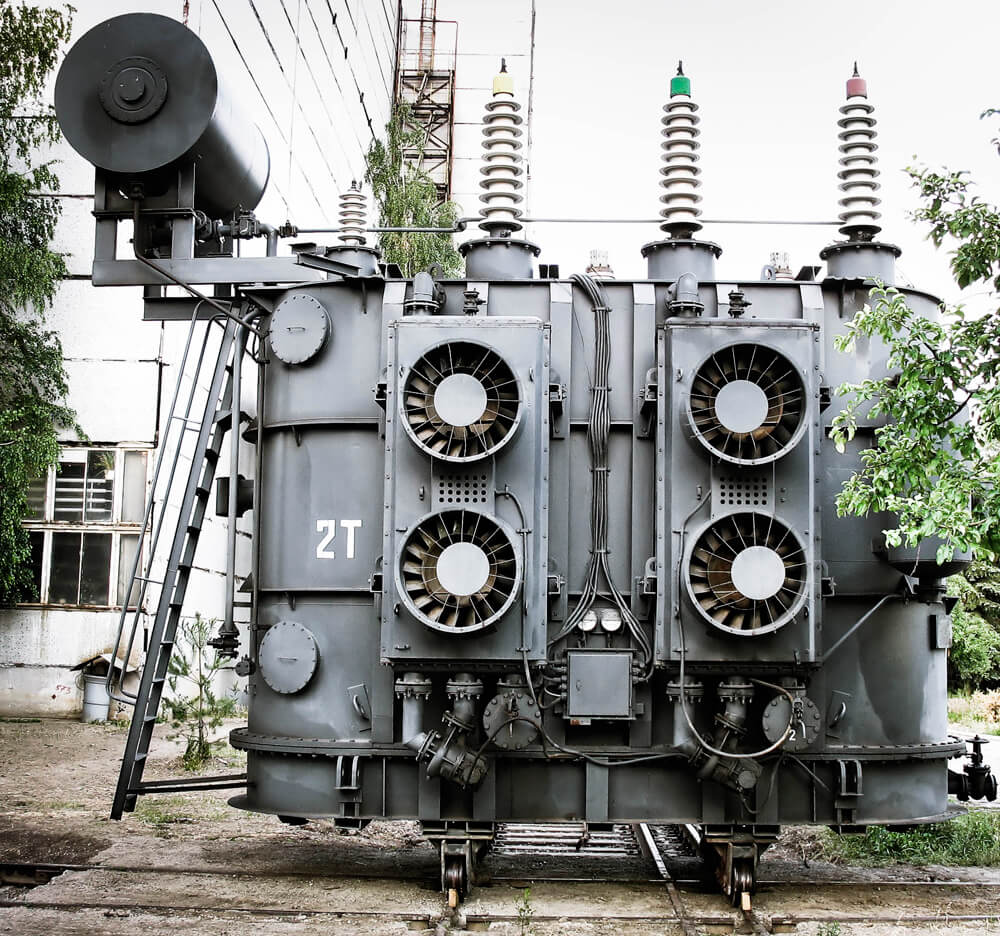

Transformer oil is a specific cooling down and shielding liquid used in electric transformers to improve operational efficiency and dependability. This oil plays an essential role in avoiding electric discharges and maintaining the needed thermal balance within the transformer - Transformer Oil Recycling. It offers to shield the conductive components, ensuring that energy is effectively transferred while minimizing the risk of short circuitsTypically originated from fine-tuned oil, transformer oil is characterized by its high dielectric toughness, low viscosity, and a robust chemical stability that permits it to endure elevated temperatures. The oil's ability to dissipate warmth generated during procedure is critical; as transformers convert electrical energy, they produce heat that should be successfully taken care of to avoid tools failure.

Furthermore, transformer oil is created to resist oxidation and degradation, which can cause the formation of sludge and other harmful results. Routine monitoring of oil high quality is necessary, as contaminants can jeopardize its insulating residential properties and overall efficiency. Comprehending the make-up and capability of transformer oil is vital for maintenance methods, ensuring the long life and functional integrity of transformers in different applications across the power market.

Value of Recycling

Why is reusing transformer oil vital for both ecological sustainability and financial effectiveness? The incorrect disposal of transformer oil can cause severe environmental dangers, consisting of soil and water contamination. By recycling this beneficial resource, we not only mitigate these threats yet also add to a cleaner community. Used transformer oil includes dangerous products that, if released right into the environment, can hurt wild animals and interrupt regional environments. Reusing assists to avoid these adverse results, enhancing the commitment to environmental stewardship.From an economic perspective, reusing transformer oil presents substantial expense savings for companies. The process permits firms to recover a high-grade product that can be recycled in numerous applications, decreasing the requirement for acquiring brand-new oil. This not only reduces operational prices but likewise reduces waste disposal expenses connected with unsafe products. Recycling supports the circular economic situation by transforming waste right into valuable resources, therefore cultivating lasting methods within the market (Transformer Oil Purification).

Advanced Recycling Technologies

As the need for lasting methods in the energy field grows, advanced recycling modern technologies have actually arised as an important solution for handling made use of transformer oil. These technologies encompass a series of innovative techniques developed to efficiently reclaim beneficial sources while reducing ecological impact.One famous technique is vacuum purification, which divides oil elements at reduced temperatures, preserving the top quality of the base oil while getting rid of pollutants. This technique enhances the recuperation price and ensures that the recycled oil fulfills market criteria. An additional substantial development is using adsorption and filtration systems, which use specialized materials to capture pollutants and recover the oil's homes efficiently.

Additionally, the integration of chemical therapies, such as neutralization and decolorization, plays a vital role in refining transformer oil. These procedures eliminate acids, sludge, and staining, leading to high-grade recycled oil that can be recycled in numerous applications.

Economic and Environmental Perks

The financial and environmental benefits of transformer oil recycling are considerable, presenting a double benefit for both market stakeholders and environmental preservation. By recycling made use of transformer oil, firms can considerably decrease functional expenses connected with buying new oil, therefore enhancing their bottom line. This procedure not just reduces garbage disposal costs but likewise permits the recovery of beneficial products, generating extra income streams.From an environmental perspective, recycling transformer oil adds to a decrease in pollution and resource depletion (Transformer Oil Purification). Proper recycling procedures reduce the danger of dangerous spills and dirt contamination, promoting and safeguarding neighborhood communities biodiversity. Additionally, repurposing transformer oil lowers the need for virgin oil removal, which usually involves environmentally devastating techniques such as drilling and refining.

Additionally, taking on advanced recycling technologies improves compliance with strict environmental guidelines, consequently protecting firms from prospective obligations and penalties. The positive influence on company social obligation efforts can enhance a company's reputation, fostering better count on and commitment among stakeholders and customers. Fundamentally, the ecological and financial advantages of transformer oil recycling emphasize its significance as a lasting practice in the energy field.

Future of Transformer Oil Recycling

Structure on the substantial economic and environmental advantages highlighted, the future of transformer oil recycling appears appealing, driven by technological improvements and enhancing regulatory stress. Innovations in recycling technologies, such as boosted purification systems and chemical handling techniques, are expected to improve the efficiency and efficiency of oil healing procedures. These advancements not only minimize waste yet also optimize the top quality of recycled oil, making it better for reuse in numerous applications.Moreover, as federal governments and regulatory bodies around the world apply more stringent environmental standards, the need for Virgin Transformer Oil lasting practices will increase. This shift will urge sectors to adopt transformer oil recycling as an important part of their functional approaches. Companies that prioritize environmentally friendly techniques are likely to obtain an affordable side, appealing to environmentally mindful customers and stakeholders.

Conclusion

The recycling of transformer oil through innovative technologies not just saves beneficial sources but also considerably alleviates environmental risks connected with garbage disposal. By embracing innovative techniques such as vacuum purification and filtering, the electrical sector can boost sustainability while all at once reducing operational costs and producing income. As the concentrate on eco-friendly practices intensifies, the future of transformer oil recycling appears promising, positioning companies to flourish in a significantly open market that prioritizes sustainability and environmental responsibility.

Transformer oil is a specialized protecting and cooling down liquid made use of in electric transformers to improve operational effectiveness and reliability. Recognizing the make-up and performance of transformer oil is essential for maintenance methods, making certain the long life and functional honesty of transformers in numerous applications throughout the power sector.

One noticeable method is vacuum cleaner distillation, which separates oil components at reduced temperature levels, maintaining the quality of the base oil while getting rid of contaminants. By reprocessing used transformer oil, companies can dramatically minimize functional prices associated with purchasing new oil, hence boosting their lower line. Repurposing transformer oil lowers the need for virgin oil removal, which commonly includes eco damaging methods such as drilling and refining.

Report this wiki page